The Hydraulic Road Blocker is the vehicle control device which can be either integrated with various parking systems or installed as single unit, designed as an effective means of controlling access to high security areas such as: airports, ports, customs, governmental buildings, banks, penitentiaries, power stations, military sites, stores, embassies, warehouses, etc. The hydraulic road blocker is designed to guarantee the full level of security. The hydraulic drive is operated by an energy accumulator that can be positioned as far away as 4 m. This facilitates placing several barriers end to end to control exceptionally wide access points. The hydraulic road blocker is available in 3 types: CPV-238, CPV-250 and CPV-275

Description

- Heavy duty 10 mm thick carbon steel anti-skid top plates

- Carbon steel plate obstacle, 4 mm thickness, welded onto a frame of thick section profiles

- The obstacle unit is articulated on two balance spring

- Optional crushproof barbed nail

- Fully painted frame and cover with galvanized steel plate

- Hydraulic power unit fully painted, available with manual operation mode which allows lowering the lifted gate plate back to its horizontal position by manual operation in power failure or malfunction cases.

- Control unit with push button box, optional remote control

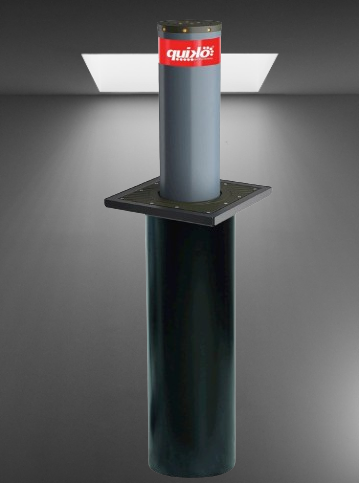

Automatic Εlectromechanical Pillar

Models: QK-CT115500 / QK-CT193700L

Overview: These automatic electromechanical bollards are designed for both private and collective contexts. The QK-CT115500 model is ideal for private spaces like parking savers and home access, while the QK-CT193700L is tailored for collective spaces such as condominiums and hotels.

Key Features:

- Type: Automatic, electromechanical retractable bollards for intensive use

- Material: Steel Fe 360 (S 235 JR)

- Break-In Resistance: 60,000 J (QK-CT115500); 110,000 J (QK-CT193700L)

- Impact Resistance: 7,000 J (QK-CT115500); 10,000 J (QK-CT193700L)

- Operating Frequency: Up to 500 operations/day

- MCBF (Mean Cycles Before Failure): 400,000 cycles

- Working Time: 6.0 s (QK-CT115500); 9.0 s (QK-CT193700L)

- Standards Compliance: 2004/108/CEE, 93/68/CEE, 2006/95/CEE, 2006/42/CEE, 99/5/CEE